How to improve your supply chain with supply chain software

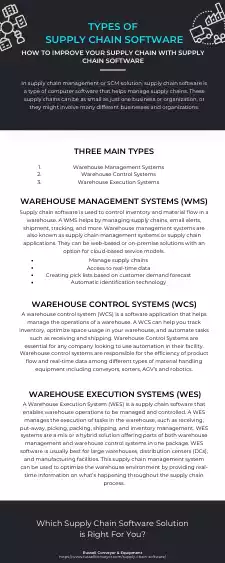

In supply chain management or SCM solution, supply chain software is a type of computer software that helps manage supply chains. These supply chains can be as small as just one business or organization, or they might involve many different businesses and organizations. There three main types of supply chain software: Warehouse Management System (WMS), Warehouse Control System (WCS), and Warehouse Execution System (WES).

Not only do these programs help with inventory levels, but they also help to improve efficiency in the supply chain process. They do this by providing reports on the status of products in real-time so there are fewer delays in production times.

Supply Chain Software: Generally speaking, supply chain software is any kind of computer program designed to assist with managing your supply chains

According to Wikipedia, “Supply chain management maximizes the efficiency of business activities that include planning and management of the entire supply chain.”

There three main types of supply chain software:

- Warehouse Management Systems (WMS)

- Warehouse Control Systems (WCS)

- Warehouse Execution System (WES)

Warehouse management systems

Supply chain software is used to control inventory and material flow in a warehouse. A WMS helps by managing supply chains, email alerts, shipment, tracking, and more. Warehouse management systems are also known as supply chain management systems or supply chain applications. They can be web-based or on-premise solutions with an option for cloud-based service models.

Features of a Warehouse management system:

- Manage supply chains

- Access to real-time data

- Creating pick lists based on customer demand forecast

- Automatic identification technology

- Barcodes

Many organizations use WMS’s to manage their supply chains. The software is available in many different forms, including stand-alone programs that can be used on their own or as modules for other ERP systems and cloud-based services.

Cloud-based services have been gaining momentum as more people opt for the convenience of access from anywhere at any time. Unlike with physical installation, there is no need to install expensive machinery or software on company servers. They can take up valuable space and increase operational costs over time when updates are inevitably needed too.

The advantages of this type include automation through EDI integration and easy access anywhere there’s an Internet connection.

What is an ERP system?

Enterprise Resource Planning (ERP) systems are comprehensive software suites that handle the core business processes of a company. These systems can include modules for Account/Financials, Inventory Management, Marketing, Customer Relationship Management (CRM), HR, Manufacturing, Distribution, and many more.

Warehouse Control Systems

A warehouse control system (WCS) is a software application that helps manage the operations of a warehouse. A WCS can help you track inventory, optimize space usage in your warehouse, and automate tasks such as receiving and shipping. Warehouse Control Systems are essential for any company looking to use automation in their facility. Warehouse control systems are responsible for the efficiency of product flow and real-time data among different types of material handling equipment including conveyors, sorters, AGV’s and robotics.

Features of a Warehouse Control System:

- Track inventory in real-time

- Optimize warehouse space usage

- Automate tasks such as receiving and shipping

If a warehouse control system is what you need you can click here to learn more about our software “Russell Control System.” The Russell Control System® (RCS) packages are a great software solution that can be installed to new and existing conveyor systems with zero impact on current system operations during setup.

Warehouse Execution Systems

A Warehouse Execution System (WES) is a supply chain software that enables warehouse operations to be managed and controlled. A WES manages the execution of tasks in the warehouse, such as receiving, put-away, picking, packing, shipping, and inventory management.

WES systems are a mix or a hybrid solution offering parts of both warehouse management and warehouse control systems in one package.

WES software is usually best for large warehouses, distribution centers (DCs), and manufacturing facilities. This supply chain management system can be used to optimize the warehouse environment by providing real-time information on what’s happening throughout the supply chain process.

Why use a supply chain software solution?

In the world of logistics, a supply chain makes up multiple companies and partners that work together to achieve high levels in transportation management. The goal for this process should be speed so goods can move from one place to another quickly with minimal hassle on both ends.

A supply chain connects all the organizations within an industry or region to provide easy access for goods produced elsewhere while sharing resources with other businesses as necessary.

Supply chain benefits include improved customer satisfaction through better quality control and reduced costs. As you can see a supply chain is a complex organism with many moving parts which is why a company needs to use a supply chain solution.

The supply chain software helps to make sense of all the movement in a supply chain by providing reports on the status of products in real-time. This allows for fewer delays in production times and increases the cost-effectiveness when you’re able to move items from one location to another quickly.

Supply chain management system can be used to optimize the warehouse environment by providing real-time information on what’s happening throughout the supply chain process.

What is a supply chain attack?

You may have heard recently about supply chain attacks since they are growing in number. In fact, according to Norton in a 2019 Security Threat Report supply chain attacks were up 78% in 2018. No industry is safe from these types of attacks according to “A New Software Supply‑Chain Attack Targeted Millions With Spyware” by thehackernews.com.

What are software supply chain attacks? They’re a cyber-attack by criminals who tamper with the processes of an organization to cause disruptions. This involves stealing customer information or company trade secrets for financial gain. This means a company must learn how to manage its cyber risk and to fully protect its network infrastructures.

How to get started with a solution that is right for you?

If you’re interested in implementing a supply chain software solution into your business, the best way to get started is by contacting an expert. An expert can help you assess your needs and find the right supply chain software for your company. You can also visit our website to learn more about the different types of warehouse management systems we offer.

Whichever system is right for your company, a company lives and dies by the data it collects and how they use that data. This is why company’s need a supply chain software system in place and operating at full capacity.

One of the most important aspects of having a successful company is making sure that resources are flowing smoothly and efficiently. The use of a supply chain management system can help you be more productive and efficient by giving visibility into your inventory, identifying bottlenecks in production, forecasting future needs for supplies or equipment. You’ll also communicate with suppliers so they’re able to meet those demands.

If you want to learn more about how we work with companies like yours (or if you need some assistance getting started), please don’t hesitate to reach out. We would love to help make your business run as smoothly as possible.

0 Comments