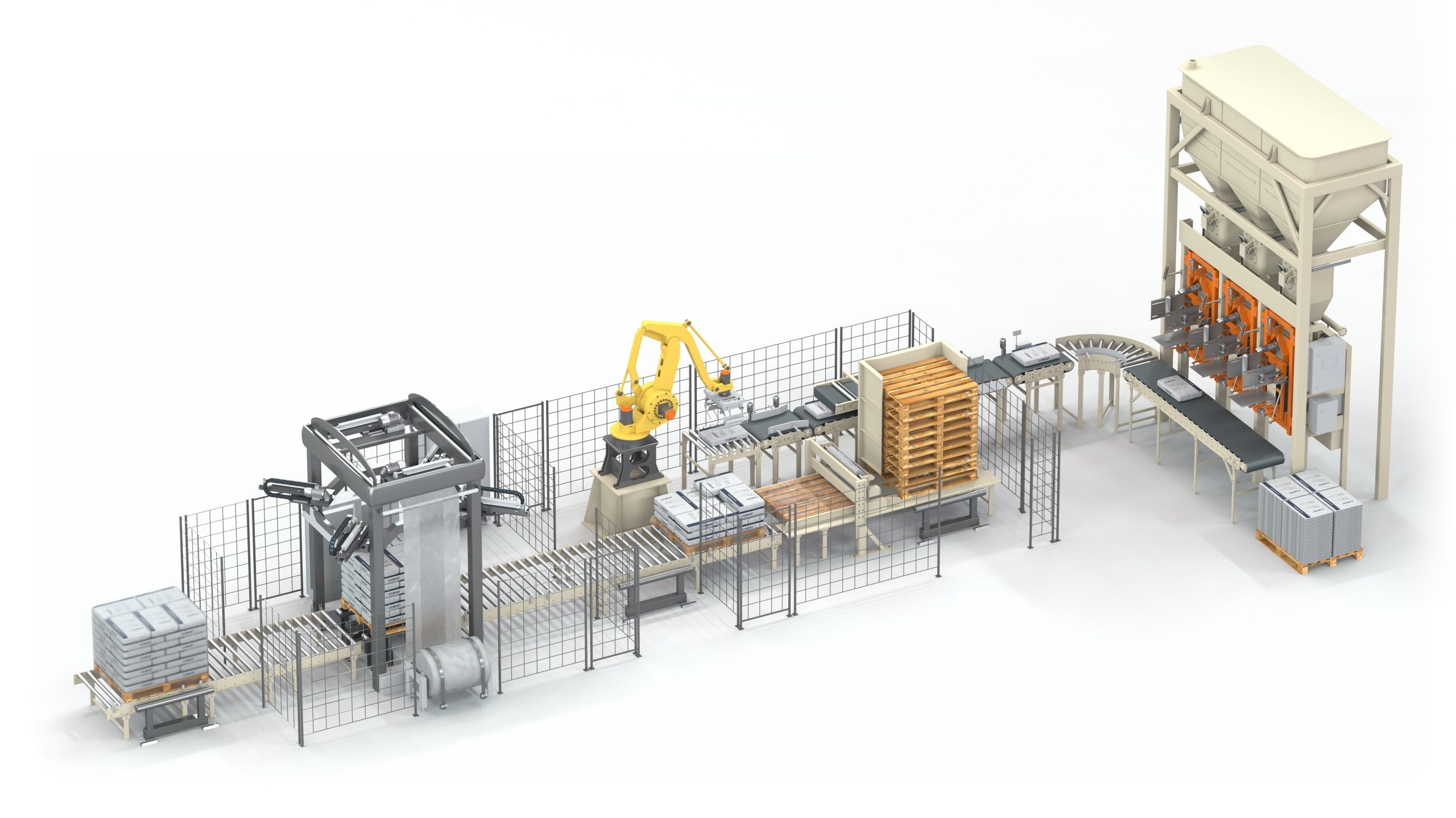

Intro to Pallet Conveyors

Thanks to the break-neck pace of warehousing and manufacturing, every detail counts when it comes to optimizing productivity and safety. Among the various factors influencing efficient material handling, pallet positioning on conveyor systems plays a crucial role that is often overlooked.

Adhering to pallet handling best practices and improving pallet alignment ensures smooth operation, reduces the risk of system failures, and extends the life of your equipment. In this blog post, we’ll explore why perfect pallet positioning matters and how to achieve it with your pallet conveyors.