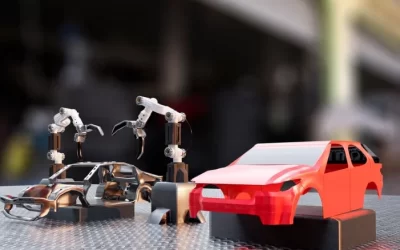

Conveyor accessories are like the sidekicks of conveyor systems, making sure everything runs smoothly and safely. They’re the tools and gadgets that enhance the performance and safety of conveyor belts. From rollers that keep things rolling to guards that ensure everyone’s fingers stay intact, these accessories are the unsung heroes of the industrial world.

Now, let’s talk types of accessories! A whole buffet of conveyor accessories exists. You’ve got your belt cleaners, like little vacuum cleaners for conveyor belts, keeping them spick and span.

Then there are the diverts and merges, playing traffic cop to ensure materials flow smoothly without any chaotic collisions. And let’s not forget about sensors and speed controllers, the brains behind the brawn, making sure everything moves at just the right pace.

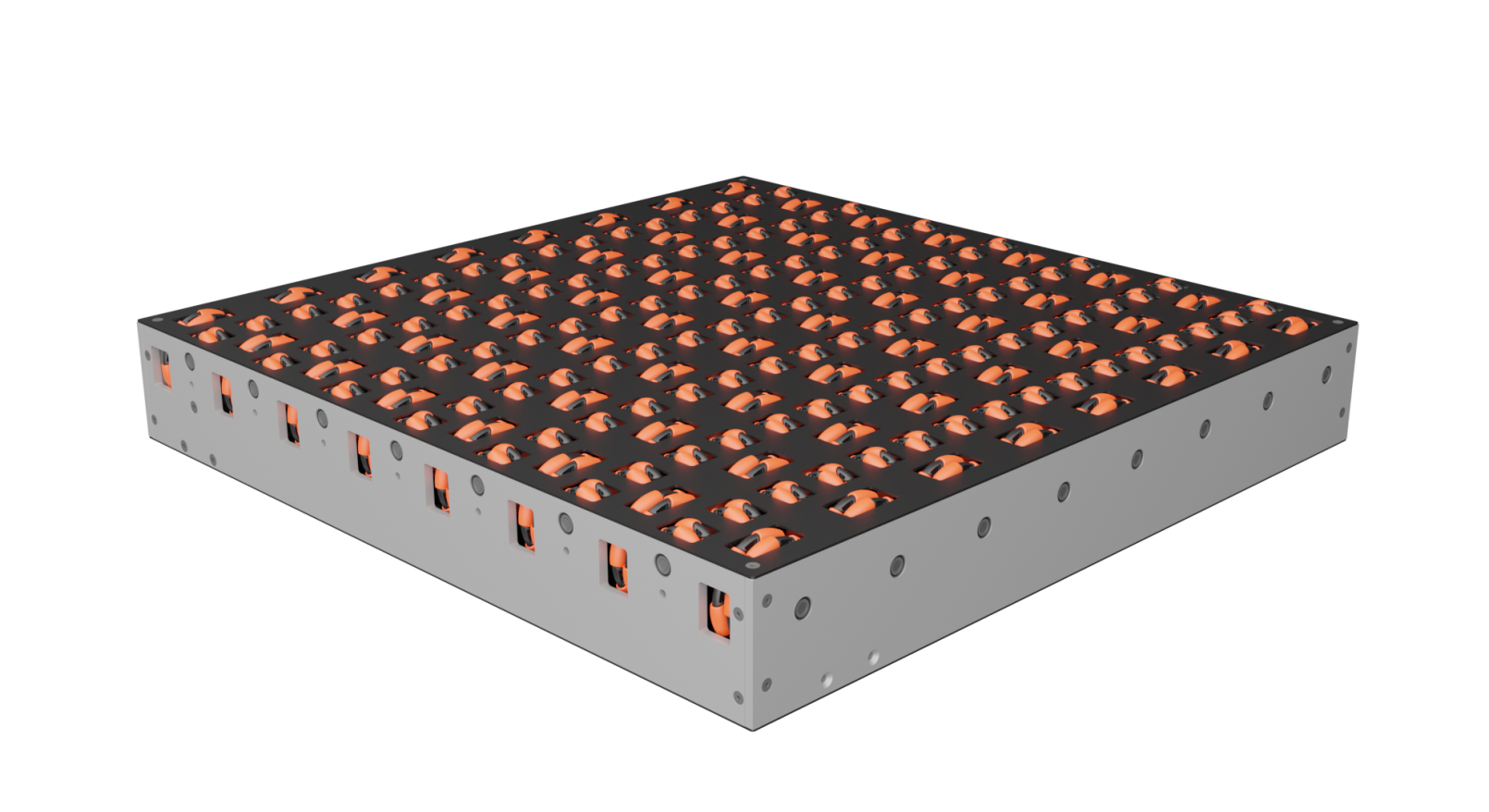

Why do we need these accessories? Each one plays a crucial role in the grand scheme of conveyor efficiency and safety. Take rollers, for instance—they reduce friction, minimizing wear and tear on the belts while keeping things moving like a well-oiled machine. Guards are the unsung heroes of safety, protecting workers from the gnashing teeth of conveyor belts.

And sensors? They’re the eyes and ears, detecting jams before they become catastrophic and keeping operations running smoothly. So, next time you see a conveyor belt zipping along, remember it’s not just the belt doing all the work—it’s the accessories that keep it in line and out of trouble.