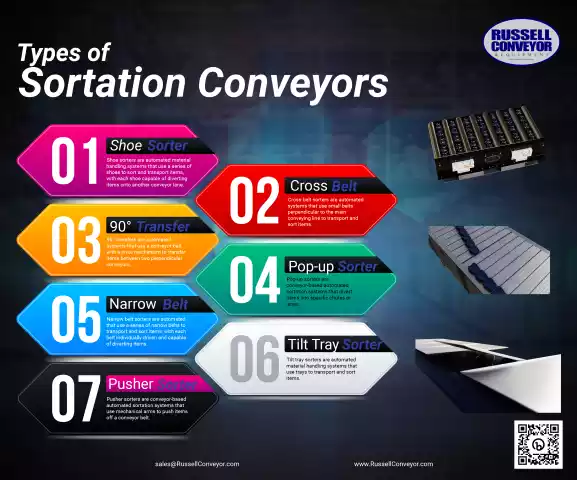

Types Of Sortation Conveyors: A Comprehensive And Informative List

True to its name, a sortation conveyor is part of a conveyor system and helps divert product from one conveyor to another. These types of conveyors are necessary in operations where product has to be sorted into different categories and distributed as groups. When deciding to implement a sortation conveyor into a facility, several factors are at play to determine where to put one and which type to use; these factors include: size and shape of material, size, shape, and weight of containers holding the material, how quickly the material needs to be distributed, and general facility configuration.

Sortation conveyors help increase productivity for operations because they move quickly and help sort materials at a rapid rate; they also help decrease labor costs because they eliminate the need to hire as many people

0 Comments